Cut to length: Decoiling Process width-220 mm, shearing capacity 8mm, Coil loading capacity- 30T

Trapezodial Cutting: Tapper cutting on using CNC plasma cutting M/c (14mm X 3.5mm X 20mm thick by plasma & 150mm thick by Oxy Flame)

CNC Press Break: Bending to ploygonbal capcity-13mm long and 8mm thick

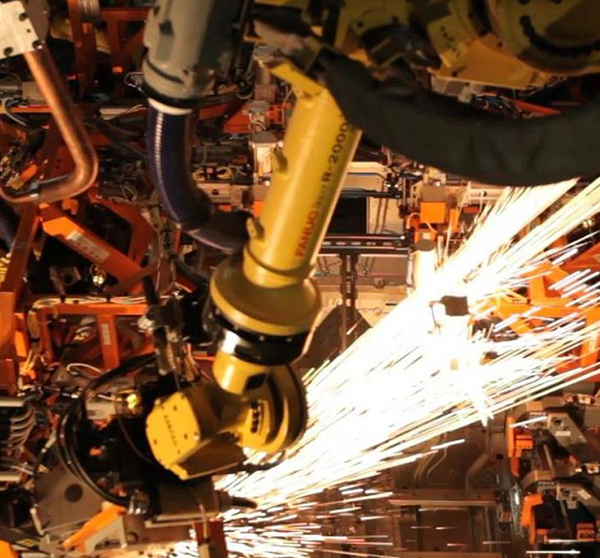

Welding: Bending to ploygonbal capcity-13mm long and 8mm thick

Griding: Longitudnal butt welding on using CNC pole closing machine

Base Plate Fitting: Base plated are welded at the bottom of the pole shaft to convert them into pole

Door Fitting: Doors are fitted generally at 50mm projection of the base Plates to place all the electrical accessories inside the pole shaft

Galvanization: Galvanization done by seven tank process in single hot dipping; method. Our Zinc Bath of 12.25m (1) X 1.05m (W) X 1.25m (D) is capable of single hot-dip galvanizing which ultimately gives better finish

Straightening & Finishing: Straightening of pole done after galvanization with the help of straightening machine. Final finishing and fittings of electrical accessories done after the completion of straightening of the poles

Loading and Dispatch: The loading is done by EOT cranes with trained person for loading.The materials are dispatched after proper loading and complete documentation